Bases Fixing Angles For M619C Mast

- ZCJJ

- China

- 5days

- 20sets

Manama Tower crane

Cairo Tower crane, Alexander Tower crane

Port Said Tower crane, Suez Tower crane

Ismailia Tower crane,

Products Specification

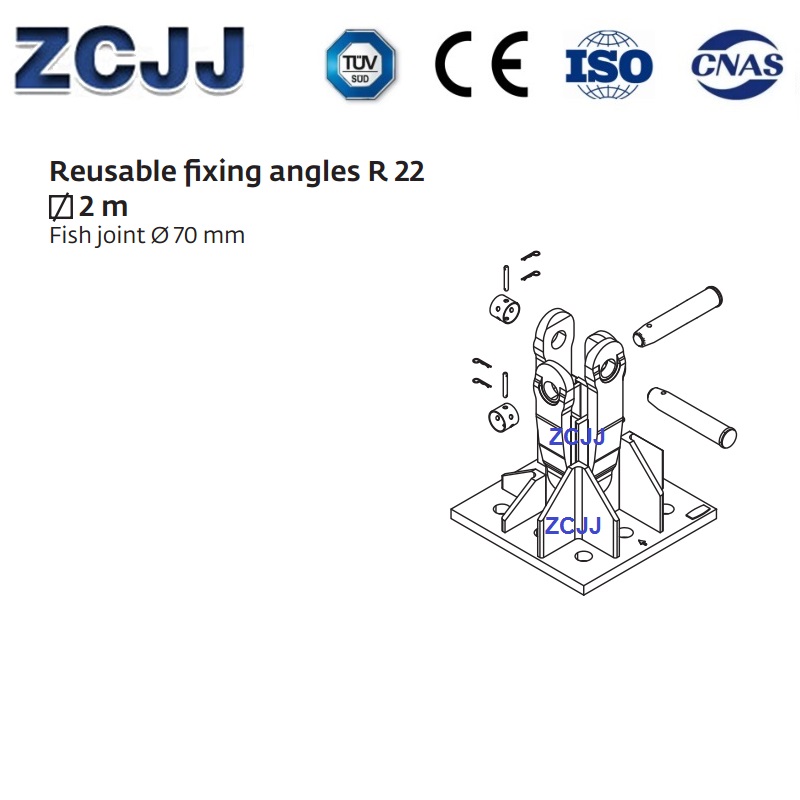

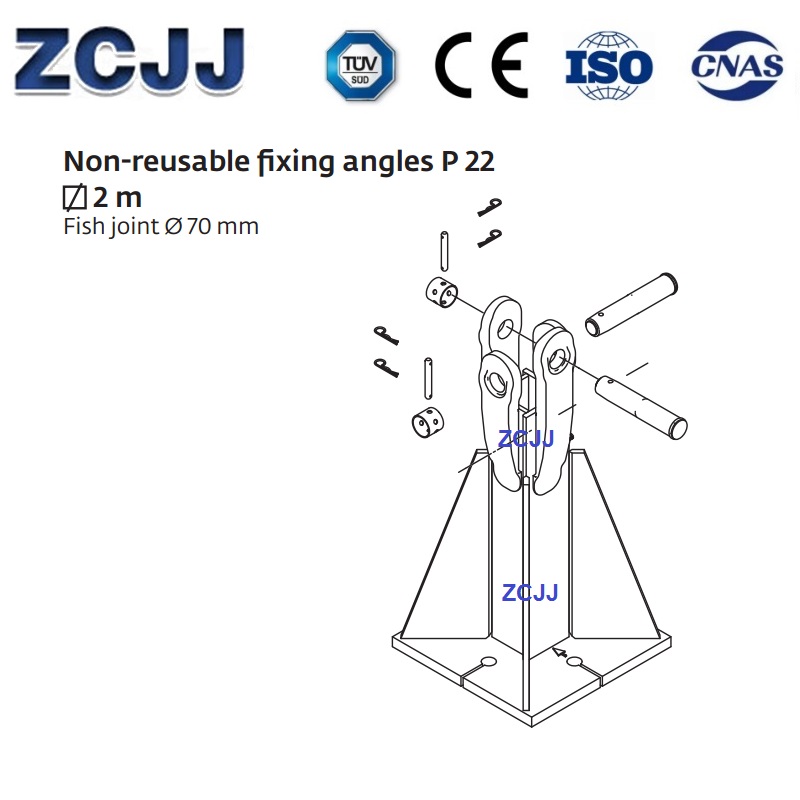

Type , Model: Bases Fixing Angles For M619C Mast

Size: 2M

Use for : M619A Mast M619C Mast ,2.13X2.13X5.32

Materials: Q345B

Process: Blasting derusting,

Painting: Under painting , Middle painting, Surface painting.

Our factory produce and supply almost all famous brand tower crane :Mast section, Anchor Frame, Fixing angle ,Adaptor and so on as good quality and price.

Bases Fixing Angles For M619C Mast

Tower Crane Knowledge sharing:

Safety technology for tower crane disassembly: technical inspection before disassembly, safety technology for disassembly operation

Technical inspection before disassembly and assembly of tower crane

A comprehensive inspection shall be carried out before the commencement of the tower crane disassembly and assembly operation to prevent any potential risks due to negligence and ensure safe operation.

1. Check whether roadbed and concrete fixed foundation meet technical requirements.

2. Carefully inspect all mechanisms, parts, structural welds, bolts, shaw shafts, hoisting mechanisms, steel wire ropes, hooks, hoisting devices, electrical equipment and lines of tower cranes, and immediately solve any problems found.

3. Inspect the hydraulic cylinder and oil pipe of the jacking hydraulic system, jacking jacket structure, guide wheel, shoe climbing claw, etc., and deal with the problems timely if found.

4. Check the main and auxiliary ground anchor frame, lifting tower winch wire rope and lifting mechanism braking system assembled and dismantled by rotating tower body method, and use it after confirmation.

5. Inspect tools, safety belts and safety helmets used by disassembling and assembling personnel, and replace them immediately if they fail.

6. Check the auxiliary machinery in the disassembly and assembly work, such as cranes, transport vehicles, etc., must have good performance, and the technical requirements can ensure the disassembly and assembly work needs.

7. Check the conditions of disassembly site, such as power supply, transportation road and working site, to see if conditions for disassembly are available.

8. The establishment of safety supervision posts and the implementation of safety measures have met the requirements.

Safety technology for tower crane disassembly and assembly

Bases Fixing Angles For M619C Mast

1. The dismantling and assembly of the tower crane must be carried out in the daytime. If the progress needs to be accelerated, some assembly and assembly work can be done at night with good lighting conditions.

2. In the process of tower crane installation and disassembly, the site must be kept clean and orderly, and sundries shall not be piled up to avoid interfering with the operation and affecting the safety.

The metal structure of the tower crane must be padded under the balk to prevent damage to the structure or structural deformation.

3. The steel wire rope for installation and erection and its fixation must meet the standards and meet the requirements of installation. Temporary facilities such as ground anchors must be firmly constructed.

In particular, before disassembly, careful inspection must be made to ensure that the ground anchors used during installation are still firm and reliable.

4. Before piece-by-piece assembly or component installation, comprehensive inspection must be conducted on the intact condition, connection condition, wire rope wearing and winding condition and electrical circuit of each part of the component.

5. In the process of erection, the stress on the structure and the wire rope is most unfavorable at the initial stage of the tower, and gradually decreases as the tower is lifted. In the process of tower removal, the maximum force is exerted when the tower is about to completely lie down.

Therefore, when the tower shelf begins to rise or is about to fall down, it must be carried out slowly and the inspection and observation of the main parts must be strengthened.

Bases Fixing Angles For M619C Mast

6. in the demolition and installation of the boom, balance arm, always maintain the balance of the crane, it is strictly prohibited to disassemble and install only one arm to interrupt the operation.

7. in the process of dismantling operations, such as a sudden power outage, mechanical failure, weather shocks, and so on and so forth can't continue to work, or work time have to need at least, must make crane installed, remove the parts reach the stable state, and has set up a locking all components connected firmly, on the top and around the center of gravity of the line at the bottom bearing center, again after check properly, may suspend operation.

8. Bolts, pins and other connectors shall be used according to installation requirements, and reliable anti-loose or protective devices shall be provided. The bolts shall be fastened with the specified pre-tightening force.

The installation of steel wire rope shall strictly comply with gb5972-86 practical code for inspection and scrapping of steel wire rope for hoisting machinery.

9. When installing the crane, the limit device and the limit device bump block of the traveling tower crane must be firmly and reliably installed. And the parts of the railing, platform, chain, support rod, retainer and other safety devices installed.

10. When dismantling the cranes that cannot be dismantled by normal methods due to damage, there must be a safe disassembly scheme approved by the technical safety department.

Bases Fixing Angles For M619C Mast

11. The installation procedures, auxiliary equipment, rigging, tools and anchor construction, etc. shall comply with the provisions in the operation manual of the machine or refer to the standard installation process.